Planet plastic: LSST’s SU President and Deputy CEO probe MIT researchers on making ‘unrecyclable’ plastics recyclable

By Kunal Chan Mehta | Article Date: 11 August 2020

Plastics becoming ‘one’ with the ocean. (Photo: LSST Marketing/Brian Yurasits)

As the world rightly pauses post-pandemic, our oceans and wildlife still progressively suffer from persistent and soaring plastic pollution. While plastics have revolutionised the world and solved many social problems, a whopping 91% of plastic is not recycled – subsequently creating colossal environmental and health problems. Adding to the challenge, some tough plastics (thermosets) are particularly impossible to recycle.

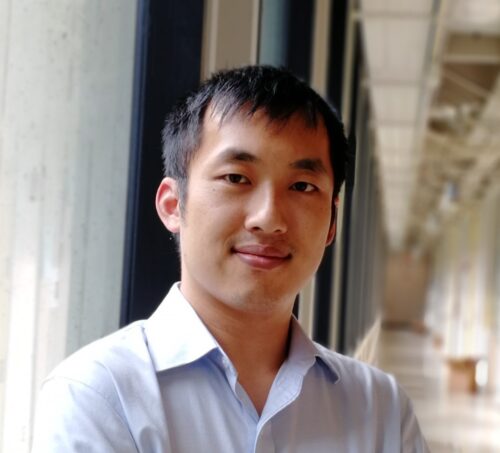

But hope is on the horizon as expert MIT researchers have discovered how to make tough non-recyclable thermoset plastics recyclable by altering how they are made without degradation of material quality. To investigate, LSST’s SU President, Irina Barariu [IB], and LSST’s Deputy CEO, Mr Mohammed Zaidi [MZ] speak with world-class chemistry Professor Jeremiah Johnson [JJ] and Dr Peyton Shieh [PS], an American Cancer Society Postdoctoral Fellow, both at MIT, about their revolutionary research that has the potential to pull down global plastic pollution permanently.

To better understand the plastic pollution catastrophe, Professor Johnson outlines his ‘Story of Polymers’ for LSST students in a video:

[IB] So what is the best way to understand the different types of plastic?

[JJ] Plastics fall into two general categories: thermoplastics and thermosets. Some examples of thermoplastics include polyethylene, polypropylene, and polyethylene terephthalate. Some examples of thermosets include acrylics, epoxies, and polyurethanes. Thermoplastics, like plastic wrap or plastic bottles, are often made up of linear polymers and can be melted at a sufficiently high temperature for recycling. In contrast, thermosets involve covalent crosslinking of polymer chains. This crosslinking gives these materials their high-performance characteristics (such as high mechanical strength or chemical resistance). However, this crosslinking also makes it difficult, if not impossible, to break these materials down into fragments that are of value and can be recycled back into new material.

[MZ] The harder they come, the harder they fall. Having reviewed your research, it seems the same applies to thermoset plastics – until now?

[JJ/PS] Current strategies to break down thermoset plastics are quite harsh. This leads to significant decomposition, which limits how we can reuse these recovered thermoset fragments. This approach is commonly known as “downcycling.” In contrast, our strategy enables the breakdown of crosslinked thermoset networks under mild conditions without degradation of material quality. The high quality of our thermoset fragments enables opportunities in “recycling” or even “upcycling” (the use of these fragments in even higher value applications).

[IB] So how have MIT chemists developed a way to modify thermoset plastics?

[JJ/PS] Our approach involves the incorporation of tailored additives (monomers) that co-polymerize within thermoset plastics. The unique property of these additives – how they co-polymerize and introduce cleavable bonds in specific locations – enables us to break down our thermosets under mild conditions at low additive loadings. At these low loadings, we maintain many of the desired mechanical properties of the parent material. Moreover, our approach does not necessitate any change in material manufacturing workflow beyond blending in our additives before curing.

[MZ] But how long was the research in progress?

[JJ/PS] This research has been ongoing for the past 18 months. We published a paper introducing some of our monomers late last year in Nature Chemistry. We found that well-controlled material degradation enabled us to tune the clearance of polymers used in drug delivery.

[IB] Can this research be applied to other plastics – such as rubber? It would be a breakthrough for vehicle tyre industries? Most tyres are considered as commercial waste sadly.

[JJ] Our research can be applied to other plastics given that the proper additives are identified and developed.

[MZ] Is this more about economics? A company must make more money on the recycled material product than what it costs to collect the plastic waste and process it right?

[JJ] Economic incentives play a significant role in the adoption of new technologies. Our work provides a new opportunity to increase the value of plastic waste, which will be essential to encourage plastics recycling. Our technology also enables on-demand degradation of thermosets, which by itself is a valuable function that could be leveraged in many applications.

[MZ]The BBC recently reported that plastic pollution is to weigh 1.3 billion tonnes by 2040 – do we have the right technology to manage this?

[JJ/PS]Our technology addresses a key portion of this challenge by enabling the recycling of plastics traditionally considered unrecyclable. To manage the overall problem of plastic pollution, we would refer you to a recent paper in Science (“Evaluating scenarios toward zero plastic pollution”). As they discuss in that manuscript, beyond new technologies for plastics recycling, it is clear that managing plastic pollution will also benefit from decreases in overall plastic consumption, increases in plastic reuse, and improvements in plastic collection workflows.

[IB]Our students have been fortunate enough to work closely with the LEGO Group – but LEGO is made from ABS plastic, which is technically recyclable. Does your research have positive news for our contacts at the LEGO Group?

[JJ/PS] Our research may have positive news for ABS plastics. We would be more than happy to talk to the LEGO team about potential opportunities to collaborate!

[MZ]Your research seems viable to licence and commercialise – is this something you are looking into?

[JJ/PS]We are actively looking into commercialisation opportunities for our technology. Towards this end, we are grateful to be at MIT, which fosters a culture of excellence in basic research while providing the support needed to bring technologies into the real world once ready.

[MZ] How can LSST students, and staff, help solve the plastic problem – to create an effective after-use plastic economy?

[JJ/PS] There are many ways to make a difference and to help create a significant after-use plastic economy, from policy to logistics to technology. Learn more about the different ways you can contribute and how they align with your interests and strengths.

Reference

Shieh, P., Zhang, W., Husted, K.E.L. et al. Cleavable comonomers enable degradable, recyclable thermoset plastics. Nature 583, 542–547 (2020). https://doi.org/10.1038/s41586-020-2495-2

Please email kunal.mehta@lsst.ac for any questions or comments about the article.

Please email irina.barariu@lsst.ac for information on LSST’s Student Union Plastic Pledge.

6 thoughts on “Planet plastic: LSST’s SU President and Deputy CEO probe MIT researchers on making ‘unrecyclable’ plastics recyclable”

Comments are closed.

Everyone is talking about this on our virtual boards and groups. So a great momentum has started thanks to MIT and LSST interviewers above. Be proud of yourselves.