3D printing industry and new career opportunities

Article Date | 2 February, 2023

.

By Shan Wikoon, Senior Lecturer in Business, LSST Elephant & Castle

.

Imagine being able to bring your child's favourite digital characters to life with the touch of a button - that's the power of 3D printing technology. No longer are we limited to just printing flat pages of text or images, 3D printing has opened the doors to creating physical objects in a wide range of materials. From custom prosthetics and medical devices to manufacturing parts for cars and aeroplanes, the possibilities are endless.

The journey of printing has been a fascinating one. From the earliest forms of printing using carved blocks and movable type to the development of larger printing presses, the ability to print text and images has undergone a significant transformation. And with the proliferation of home printers, the printing industry has undergone another revolution.

Now, with 3D printing technology, we are reaching new heights of innovation. In this blog, we will explore the current applications of 3D printing and its potential career opportunities. We will delve into the ways this technology is changing the world around us and how it has the power to revolutionise the way we manufacture and create physical objects. Join us as we explore this exciting and rapidly evolving field.

What is 3D printing (additive manufacturing)?

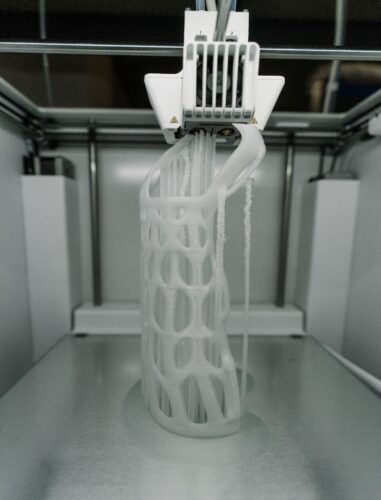

3D printing technology, also known as additive manufacturing, creates physical objects from digital designs. It involves the use of a 3D printer, which reads a digital design and builds up the object layer by layer using materials such as plastic, metal, or composite materials.

One of the key advantages of this technology is its ability to produce complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. This is made possible by the digital nature of 3D printing, which allows for the creation of detailed, highly precise digital models that can be used to guide the printing process.

For example, a traditional manufacturing method such as injection moulding is limited by the complexity of the mould that must be created. A 3D printer, on the other hand, can create a wide range of complex geometries without the need for a mould, making it possible to produce parts that are highly customised and tailored to specific needs.

A few examples of products already produced by this amazing technology include:

➢ Medical implants: e.g., bones, joints, dental restorations and other body parts. These implants are often customised to fit the specific needs of the patient and are produced using materials such as titanium, polymers, and ceramics.

➢ Prosthetics: e.g., a patient-specific prosthetic, the design of which can be highly complex and unique to the individual. With 3D printing, it is possible to create customised, precisely-fitted implants that are tailored to the patient's specific needs, providing a much better fit and function than a generic implant.

.

➢ Consumer products: e.g. phone cases, jewellery, and other decorative items. These products are produced using materials such as plastics, resins, and other polymers.

➢ Food products: chocolate, pizza, and other edible items.

➢ Clothing: shoes, hats, and other garments

➢ Art and sculptures: 3D printing has been used to produce a wide range of art and sculptures, including statues, figurines, and other decorative items.

➢ Parts for aerospace and automotive industries: complex geometries with internal structures can be 3D printed, such as hollow spaces and internal channels, which can be used to reduce the weight of a part while maintaining strength and durability. The weight savings can result in significant fuel savings and increased efficiency.

.

Different type of additive manufacturing technologies

There are several different technologies, each with its own unique characteristics and capabilities. Some common 3D printing technologies include:

➢ Fused Deposition Modelling (FDM): involves melting and extruding a filament of plastic or other material to build up the object layer by layer.

➢ Stereolithography (SLA): uses a laser or other light source to cure layers of resin into solid objects.

➢ Selective Laser Sintering (SLS): uses a laser to sinter powdered material into solid objects layer by layer.

➢ Electron Beam Melting (EBM): uses an electron beam to melt layers of metal powder into solid objects.

➢ Binder Jetting: involves using a binder to bind together layers of powdered material to create solid objects.

Each of these 3D printing technologies is suited to different types of applications and materials. For example, FDM is well-suited for creating prototypes or producing parts with simple geometries, while SLS is better suited for producing functional parts with complex geometries (see: https://www.ge.com/additive/additive-manufacturing)

The step-by-step process of Fused Deposition Modelling

➢ To create a 3D-printed object, the first step is to design the object using computer-aided design (CAD) software or by scanning a physical object to create a digital model. The digital design is then exported as a 3D printer-ready file, such as an .STL or .OBJ file.

➢ The 3D printer is then set up and prepared for printing, which usually involves loading the printer with the appropriate materials and making any necessary adjustments to the printer's settings. Once the printer is ready, the prepared file is sent to the printer and the printing process begins.

➢ As the printer reads the digital design, it lays down successive layers of material to build up the object. The thickness of these layers can range from a few micrometres to several millimetres, depending on the printer and the desired level of detail.

➢ After the object has been printed, it may need some post-processing to remove any excess material or smooth out the surface.

Advantages of prototyping with 3D printing

A prototype is a preliminary model or sample of a product, system, or idea, used for testing and demonstration purposes. In product development, a prototype is typically used to evaluate the design and functionality of a proposed product before it is finalised and mass-produced.

With traditional prototyping methods such as CNC machining or injection moulding, the process of creating a physical prototype can be time-consuming and costly, especially for complex or customised designs.

3D printing allows for the direct production of a physical prototype from a digital model. This can be done quickly and at a relatively low cost, as there is no need for expensive tooling or moulds. Additionally, 3D printing technology allows for a high degree of design freedom, as it can produce complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods. This has led to an acceleration of product development and an increase in innovation in various industries.

One example is in the automotive industry where companies are using 3D printing to produce complex and customised parts for cars, such as engine components and door handles. This allows them to test different designs and materials, and to quickly make changes to the design before mass production.

Operations management and 3D printing

Technology can have a significant impact on operations management in a variety of ways. Here are a few examples:

➢ Customisation: the production of customised parts and products, which can be more efficient than the mass production of standardised items. This can lead to increased flexibility and responsiveness to customer needs.

➢ Speed and lead time: there is no need to use the traditional manufacturing process of creating moulds and tooling.

➢ Inventory management: the parts can be produced as needed rather than being stockpiled. This can reduce the costs associated with storing and managing inventory.

➢ Quality control: the production of high-quality parts with minimal defects, as the production process is automated and does not involve the handling and assembly of multiple parts.

Sustainability: 3D printing can reduce waste and the environmental impact of manufacturing, as it uses less material and energy than traditional manufacturing processes.

➢ Overall, 3D printing can bring efficiency and flexibility to operations management and can be a valuable tool for companies looking to streamline their production processes.

The dark side of the technology

The impact of 3D-printed illegal weapons is a complex and controversial issue that has garnered significant attention in recent years. 3D printing technology has the potential to enable the production of low-cost and customisable weapons. 3D-printed guns could make it easier for individuals to obtain firearms, particularly in countries with strict gun control laws. This could increase the number of firearms in circulation and potentially lead to an increase in violence and crime.

The production and distribution of 3D-printed guns could pose significant legal and regulatory challenges, as it may be difficult to enforce existing laws and regulations on firearms in the face of new technologies.

Intellectual property violations are another significant issue. 3D printing has the potential to facilitate the unauthorised reproduction of protected intellectual property, such as patented designs or copyrighted works.

Read The BBC news story, ‘3D-printed guns: Warnings over growing threat of 3D firearms’ on https://www.bbc.co.uk/news/technology-63495123.

Future advancement of additive technology

The new generation of 3D printers that are multi-material and multi-layer will be a game-changer. One such printer is capable of producing fully functional electronic circuits in a single printing process.

4D printing, also known as smart or dynamic 3D printing, is a form of additive manufacturing that involves the creation of 3D-printed objects that are capable of changing shape or function over time. This is achieved by integrating materials that respond to stimuli such as temperature, humidity, or light into the 3D printing process.

The potential applications of 4D printing include the production of medical implants that are capable of adapting to the body's needs, self-assembling structures that can be easily transported and assembled on-site, and smart textiles that can change shape or function in response to stimuli.

Overall, 4D printing represents a significant advance in the field of additive manufacturing, with the potential to create truly dynamic and adaptable products and structures. However, it is still a relatively new and emerging field, and much research and development are needed to fully realise its potential.

See also:

What are 3D-printed Electronics?

4D Printing: All you need to know in 2023

Will 3D printing industry provide new career opportunities for Higher Education/university graduates?

Are you curious about the limitless possibilities of 3D printing and the career opportunities it holds? The field of 3D printing is rapidly expanding, providing a diverse range of career paths such as

➢ Professionals with expertise in computer-aided design (CAD) and other design software can work on the development of digital models for 3D printing.

➢ Professionals can work in the optimisation of 3D printing processes and materials.

➢ Professionals with expertise in 3D printing technology can work on the operation and maintenance of 3D printing equipment, as well as the production and quality control of 3D-printed products.

There are a variety of knowledge and skills that are valuable for professionals working in the 3D printing industry, including:

➢ Computer-aided design (CAD): Proficiency in CAD software as it is used to create digital models for 3D printing.

➢ 3D printing technology and processes: Familiarity with the various types of 3D printing technologies and processes, as well as their capabilities and limitations.

➢ Material science: Knowledge of the properties and characteristics of different materials used in 3D printing, as well as how they respond to different printing processes.

➢ Manufacturing and production: Proficiency in manufacturing and production processes, including quality control and continuous improvement.

➢ Problem-solving: The ability to identify and solve problems that may arise during the 3D printing process.

➢ Creativity: The ability to think creatively and come up with new ideas and solutions will drive innovation and development in the 3D printing industry.

As a student, these are the skills that will make you stand out and be the next big player in the 3D printing world. Imagine the impact you could make in this field by being a part of the innovative solutions and products that are being created every day. Don't miss out on the chance to shape the future and make your mark in the world of 3D printing.

In a recent interview, LSST discussed career prospects within the 3D printing industry with a leading company. Read Additive-X shares its 3D printing story with LSST.

Further reading:

Sharing is caring!